CIRAS' next Iowa Vendor Conference is scheduled for Thursday, August 10 in Des Moines. Wondering whether it's worth your time? Don't just take our word for it. Here are some of the reviews from business leaders who attended last year's conference:

Month: June 2017

State of the State: Looking for Clues to Competitiveness in Iowa’s Manufacturing Wages

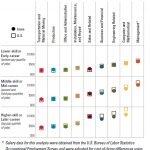

Wage levels both reflect and influence the competitiveness of Iowa’s manufacturing sector. The average manufacturing worker in Iowa earned $42,470 in 2015, about 86 percent of the national average. Accounting for Iowa’s lower cost of living improves the picture, boosting the state’s pay on a price parity basis to 95 percent of the U.S. average. The pay differential* for Iowa’s manufacturing workers varies by the type of work they perform. Iowa’s average production worker, for example, earns 104 percent of the average U.S. production worker’s wage. Iowa‘s engineering-related workers average just 90 cents for every dollar earned by their national peers. This article demonstrates how closer attention to wage distributions might inform the state’s innovation and workforce attraction/retention efforts. For our example, we classify Iowa and U.S. manufacturing jobs along two dimensions: occupation and inferred skill or experience level. Nine occupational groups are considered, which together account for 95 percent of all manufacturing jobs.

Iowa Program Helps Companies Afford Some Added Expertise—By Adding Interns

Interns at ALMACO get much more than an overview of the company’s custom-built agricultural equipment. They become part of the team. Brian Carr, ALMACO’s vice president of engineering, said student employees at the Nevada-based company get directly involved in completing projects—from initial design, through problem-solving challenges, to the eventual result.

Account Manager Spotlight: Brenda Martin

CIRAS government contracting specialists know a lot about Iowa businesses, so we're offering these few questions and answers to help you learn a little more about them:

CIRAS Assisting Effort to Improve Iowa’s Targeted Small Business Program

Iowa officials are working to streamline and improve a state preference program for small businesses to make it easier to understand and quicker for companies to access.

ISU Solar Car, with CIRAS-printed Parts, now Touring Iowa to Prep for Outback

Members of Iowa State University’s PrISUm solar car team are heading to Australia this fall for the team’s first-ever international competition. When they go, they’ll be competing in a vehicle that includes several parts constructed by CIRAS.

Digital Manufacturing is coming. Get ready.

Do you hear terms like "digital manufacturing," "Industry 4.0," and "Internet of Things," but wonder how any of those things could actually impact your company? Are you sensing that something is coming but uncertain of what it all means? CIRAS wants to help.

Faces of Iowa Industry: Joe Meier (Geater Machining & Manufacturing Co.)

Every so often (starting now), CIRAS intends to take a moment and tell you a little bit about the people who make Iowa businesses better: Joe Meier started out as a sea-savvy machinist and worked his way to becoming vice president of operations for fast-growing Geater Machining & Manufacturing Co. in Independence. Below you’ll find his secret to success and what he’d improve about Iowa industry if he could.

Gross-Wen Technologies: Using Algae to Clean City Sewage

A pioneering enterprise formed to treat municipal and industrial wastewater with algae hopes to launch into large-scale operation this summer with construction of its first functional, city-sized test facility in Dallas Center, Iowa. Gross-Wen Technologies, a company launched by Iowa State University researcher Martin Gross and professor Zhiyou Wen, has been working for roughly two years on plans to turn its discoveries into a two-pronged business. The Gross-Wen approach uses tanks of wastewater, vertical conveyor belts, and a special biofilm to grow and harvest the algae. Once water treatment is complete, the algae can be scraped off the belts and sold as a fertilizer, effectively subsidizing the cost of running a large-scale treatment system.7