A Sumner, Iowa, manufacturer of emergency vehicles believes it’s on the cusp of a major innovation after Iowa State University engineering students helped the company develop a new design for a side-entry ambulance door.

A Sumner, Iowa, manufacturer of emergency vehicles believes it’s on the cusp of a major innovation after Iowa State University engineering students helped the company develop a new design for a side-entry ambulance door.

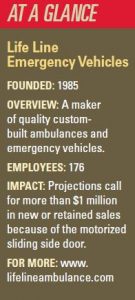

Life Line Emergency Vehicles, a maker of custom ambulance bodies since 1985, was scheduled to go to a national trade show this fall with a working prototype of its first ambulance with a motorized sliding side door—a new feature that’s expected to make it safer and more convenient for emergency medical crews to operate in tight spaces or along the side of a highway.

“Any time an ambulance pulls over to the side of the road on a restrictive street, getting the side door open becomes an issue,” said Jacob Spiegel, Life Line’s head of research and development. For example, hinged doors that swing open near traffic have a tendency to block views of the road and may create a hazard for EMS workers.

Other ambulance makers have been selling sliding side-door models for years, but Life Line’s new patent-pending entry appears to be the first motorized offering.

“We have always tried to be a leader in the industry,” Spiegel said. “We’ve always tried to be out in the forefront…. I think this is going to be a very big deal because it gives us something that the rest of the industry doesn’t have.”

The new product is arriving roughly two years after the privately owned Life Line was sold to Folience Inc., an employee stock ownership plan that purchased the ambulance firm in July 2017 (see page 3), making the company 100 percent employee owned. To help Life Line grow, Folience reached out to CIRAS and Iowa State University for assistance.

The sliding side door was “something that people had been talking about in the industry, so it was a good starting point,” Spiegel said. “There are a lot of things that have to be addressed in a sliding door. It’s a complex mechanism, but this is a good fit for a bunch of engineering students.”

“We didn’t want to be an ‘us-too,’” said Randy Smith, Life Line’s director of operations. “We wanted it to be unique and to challenge us.”

Eight mechanical engineering students visited Life Line in the fall of 2018 to begin roughing out the new door’s design as part of a senior capstone project—a requirement that Iowa State engineering students must complete before graduation to demonstrate that they can apply what they’ve learned to real-world problems. A second group of capstone students then developed the design even further the following semester.

Life Line engineers took over the project in May and began working it through the final tweaks of becoming a production-worthy design.

“The students were magnificent, but they ran into some problems that modeling it on a computer doesn’t predict,” Spiegel said. “They did a bang-up job; but until you build the first prototype, you don’t really know how it’s going to work.”

“The students were magnificent, but they ran into some problems that modeling it on a computer doesn’t predict,” Spiegel said. “They did a bang-up job; but until you build the first prototype, you don’t really know how it’s going to work.”

Life Line planned to publicly unveil the new ambulance this fall at EMS World Expo 2019, a major trade show in New Orleans. But the new vehicle still will require safety testing—meaning it may take another year before the company will see significant new sales.

But Spiegel said Life Line is confident that the industry’s future includes sliding side doors. It’s simply what the customers want.

“We are a custom-built manufacturer,” he said. “Everything we make is custom. We take great pride in the durability and the longevity that people get out of a Life Line ambulance. I think this will dovetail nicely with our existing product line.”

“If we deliver something that is a benefit to the customer and it’s seen as value added, then it’ll sell itself.”

> For more information, contact Carey Novak at cenovak@iastate.edu or 515-408-4257.

A version of this article was published in the Summer 2019 edition of CIRAS News. To read more of that edition or others, please explore elsewhere on our website.