Company president and CEO Roger Hargens recently acknowledged that at least “a part of” that expansion became possible thanks to work the company landed as a result of CIRAS-arranged tests performed by Iowa State University’s Center for Nondestructive Evaluation (CNDE).

“Obviously the partnership was great, and their proximity was fantastic,” Hargens said of CIRAS. “Their willingness to help us in a very fast fashion was really beneficial for us and our customer. They really jumped through hoops for us.”

Accumold declined to discuss specifics of the project, but company officials said it boiled down to this:

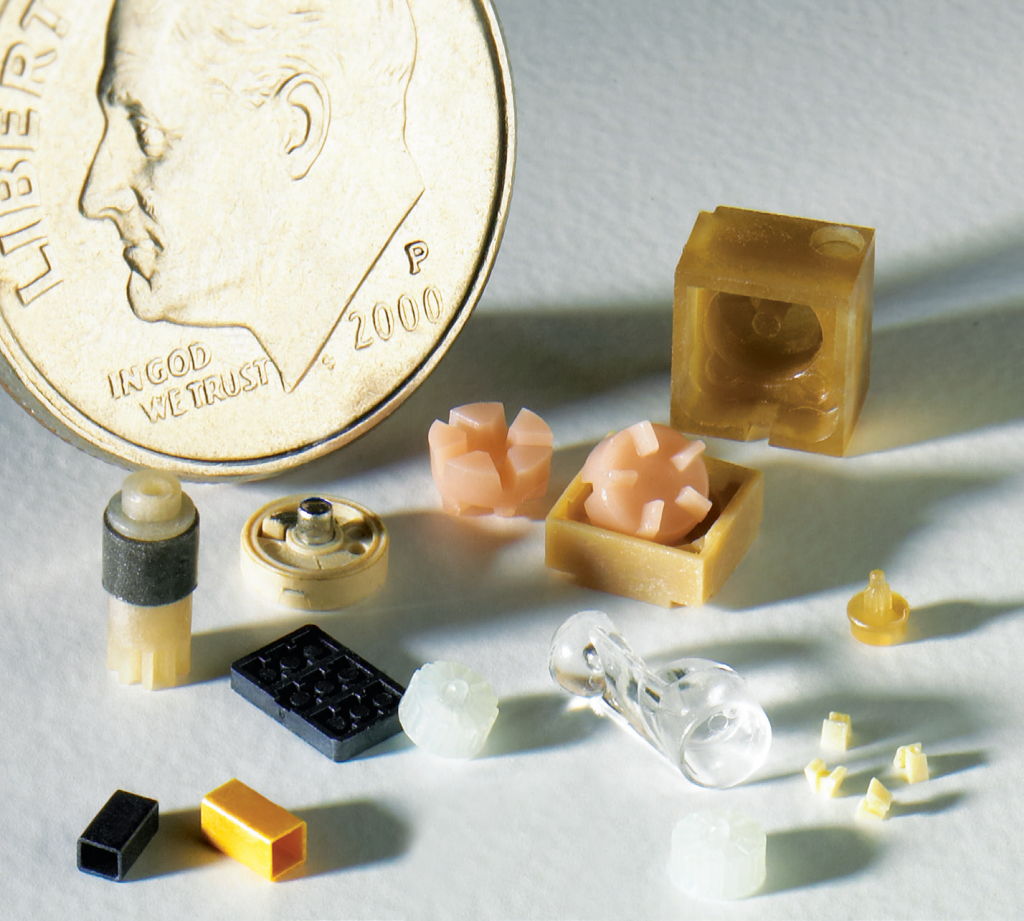

Last spring, Accumold developed a need to verify its work on a prototype “smart device.” The project involved assembling three microelectronic components into one plastic part roughly 2.5 mm by 1 mm. Accumold needed to prove that it could reliably produce parts with everything in the correct location, that parts would be functional, and that they would hold up in a harsh environment.

“Typically, our customers will do that testing themselves,” said Aaron Johnson, vice president of communications. “But because of the nature of this particular project and the customer and the speed, we took on that process. It had to get done.”

The company turned to CIRAS and CNDE, where program manager Dave Utrata used x-rays to examine a sampling of parts. “We had to do geometric magnification to make an x-ray image of a small object big enough to say, ‘OK, that’s good and that’s bad,’” Utrata said.

“Setting up the test often takes longer than the test,” he said. “Parts handling is a big issue. Knowing what to do, being able to rapidly adjust and fine-tune x-ray system parameters . . . . It’s learning how to handle these small things without going, ‘Oops . . . ’”

Hargens said the tests ultimately had “a significant impact on our relationship with this customer and our ability to get more business from them.”

It was a challenging project” for CIRAS, Hargens said. “It wasn’t a walk in the park by any means. But they did a very nice job.”

> For more information about product testing, contract Chris Hill at chhill@iastate.edu or 515-294-5416.

This article originally appeared in the Summer 2015 edition of CIRAS News. You can find the rest of this issue and more of CIRAS News on our website.