Keith Vorst doesn’t think outside the box so much as he thinks about the box—and how it affects everything around it.

Vorst, an associate professor in Iowa State University’s Department of Food Science and Human Nutrition, also is director of the university’s new Polymer and Food Protection Consortium. He has spent the last year working to build a national center for packaging research and expertise—a place where companies in Iowa and elsewhere can go to assess the design, safety, function, and value of the packaging that envelops their products.

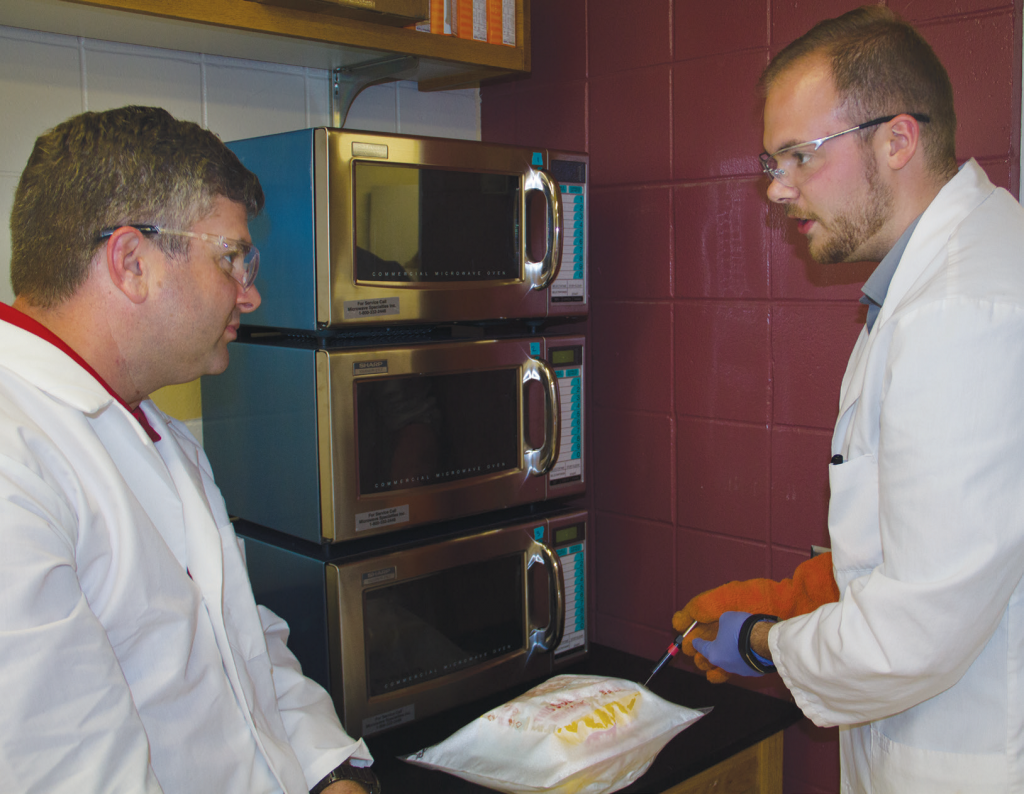

Keith Vorst and graduate student Nathan Davis evaluate the performance and safety of microwave popcorn

“We’re trying to be a packaging clearinghouse for industry,” Vorst said. “Basically, if it’s packaging and recycling and food safety- or quality-related, then Iowa State needs to have a hand in that conversation when industry makes its decisions.”

Packaging is a major expense for many businesses. A 2013 Smithers Pira study projected that the global packaging market will top $975 billion by 2018. Nearly $284 billion of that money will be spent by food businesses, who face challenges both from ever-changing government regulations and from growing consumer expectations regarding safety and sustainability.

Yet most companies don’t have in-house expertise to explore alternatives.

“A lot of companies don’t revisit their packaging often enough,” Vorst said. “They’ll come up with a design, put it into production, and the same design becomes part of their standard operating procedure for years. In many cases, those designs are due for refinement.”

Enter the consortium, which is part of Iowa State’s College of Human Sciences and the College of Agriculture and Life Sciences.

Vorst has established a multidisciplinary, centralized hub for companies and state regulators to receive independent reviews of packaging. Before the consortium, Iowa companies had access to data only from their suppliers or universities in other states. Now, for an annual membership fee, companies can access a hub of research and expertise.

The consortium’s members, currently 10 companies, choose up to five large research projects to complete each year for the benefit of all members. Members also have access to reserved open lab time for smaller, company-specific packaging research projects.

One Iowa business that already has benefited from the consortium is American Pop Corn Company. The company has been exploring new cost-effective and healthy ingredient solutions for its products and new performance criteria for its packaging. Mike Carr, director of quality assurance and product development, describes microwave popcorn as a nearly $1 billion industry, with the “product package just as important as the microwave in providing piping hot, delicious microwave popcorn snacks.”

American Pop Corn Company and one of its packaging suppliers, Coveris, found the consortium with help from CIRAS. Carr said the company’s available technical resources for packaging research “were far outmatched by the researchers within the consortium. Joining the consortium gave us the agility and depth of resources needed to find answers.”

Vorst’s team recently conducted research to validate the safety and seek ways to improve the performance of microwaveable popcorn packaging. Vorst will soon be sharing the results with consortium companies.

American Pop Corn Company officials say it’s too early to discuss the economic implications of that research. But Tom Elsen, vice president of marketing, acknowledged that there would be a “tremendous competitive advantage” to finding packaging and alternative ingredients that create an environmentally friendly and healthier product for consumers.

While the consortium’s research focuses on food packaging, it has capabilities to serve other sectors, such as the automotive industry. “We can be an advocate for both the consumer and the company when we meet with regulatory agencies,” Vorst said. “We serve both interests.”

Vorst also presented at a CIRAS Packaging Short Course in October, giving companies an opportunity to work hands-on with design, simulation, and testing technology in the packaging consortium’s labs.

Vorst’s goal is to grow the consortium to 20 members within the next year. Membership applications are currently being accepted.

For more information, contact Brenda Martin at bkmartin@iastate.edu or 515-570-5282.

This article originally appeared in the Fall 2015 edition of CIRAS News. You can find the rest of this issue and more of CIRAS News on our website.