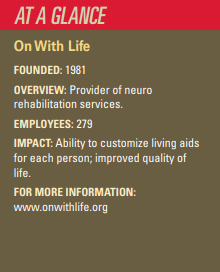

An Ankeny-based rehabilitation facility has partnered with CIRAS to develop a cost-effective solution to an everyday challenge faced by some of the people it serves.

On With Life (OWL) works with people who have sustained a traumatic brain injury, stroke, concussion, or other neurological disease. Many of the people it serves use wheelchairs and have impaired use of their hands due to their injuries. OWL staff were searching for ways people could safely heat food on a stovetop, even when they couldn’t see over the sides of the pot they were using. They found their answer at a CIRAS virtual tour of Iowa State’s Digital Manufacturing Lab. The tour showcased the use of 3D printing to create customized pieces for various business needs.

“What CIRAS was doing for businesses seemed analogous to the work of developing custom living aids,” said Joe Walters, OWL director of analytics. “The challenge was figuring out how a medical facility like ours could explore the possibilities of the technology and bring it in-house, assuming it made sense for us.”

Chris Hill, director of the CIRAS Technology Assistance Program, worked with OWL to create a 3D printed mirror assembly that could be quickly inserted into a mount on a wheelchair. The mirror enables hands-free monitoring so the user can safely heat food on their own. Iowa State student and CIRAS intern Cassie Swacker, who is an OWL volunteer, and Jake Behrens, a CIRAS project manager, provided design and printing assistance.

“A strength of 3D printing is the ability to quickly and cost effectively make a high mix of parts. Each OWL client can have unique needs, so being able to address them with 3D printed parts will change lives,” said Hill.

The original scope of the project was expanded during the design process when other applications became apparent. For example, the design team discovered that by splitting the rod, the mirror could be used to search for dropped items or to look at the contents on the upper shelves of cupboards.

The success of the mirror device led to exploring other ideas, including a cupholder that can be mounted to wheelchairs.

“Cupholders that can hold the larger water jugs our persons use aren’t available for purchase,” said Walters. “In asking CIRAS for assistance, they proposed developing an adjustable cupholder that can be used as a standard holder on any wheelchair.”

The experience OWL has had with 3D printing has been so positive that they decided to raise funds to purchase their own equipment. Walters and Hill recently collaborated on a presentation showcasing the use of 3D technology in developing customized assistive devices for people with disabilities.

“It’s been inspiring to work with the CIRAS team,” Walters said. “They not only brought our initial idea from concept to device, but they have been generous with sharing their time and expertise. Adopting a new technology requires a learning curve, and they have been there as we progressed through the process.”

The project has also given Swacker a glimpse of the career path she hopes to follow after her Iowa State graduation. Swacker is a sophomore majoring in mechanical engineering with a biomedical engineering minor.

“This project has given me the chance to learn about and experiment with a variety of engineering technologies, and to get experience with following the design process,” she said. “It’s easy to get caught up in classes and lose sight of what I’m working toward. Working on this project has helped me look forward to my remaining years of study and my future career as an engineer.”

For more information, contact Chris Hill at chhill@iastate.edu or 515-313-8251.